JRC DDBMI – Josef Ressel Centre for Data-Driven Business Model Innovation

Projektdaten

Laufzeit: 2023-01-01 bis 2027-12-31

Projektleiter: FH-Prof. DI Dr. Herbert Jodlbauer

Partner: , Pöttinger Landtechnik GmbH, Tiger Coatings GmbH, Miba AG

Fördergeber: Christian Doppler Forschungsgesellschaft

Executive Summary

The Josef Ressel Centre (JRC) addresses data-driven business model innovation. The term data-driven refers to the aspects of data-driven value creation, value delivery, and value capture and to data-driven innovation processes for business modelling. The JRC for data-driven business model innovation (JRC DDBMI) focuses on incumbent (well-established) manufacturing companies and on business model innovation in terms of reconfiguration and transition from the current business model to a novel data-driven one. The main objectives of the JRC DDBMI are to support incumbent manufacturers in recognising the necessity and urgency of business model innovation, ensuring the establishment of a sustainable (referring to the three objective levels: economic, environmental, and social) business model, reconfiguring their existing business models by utilising data, performing the transition from the old to the new business model, and using data-driven tools and process models for business model innovation efficiently and effectively. To meet the above objectives, the JRC DDBMI consists of five research topics:

- Lessons learned from success and failure of business model innovation cases

- Transforming data into value

- Sustainable business models and prediction of sustainable outcomes

- Data-driven ecosystems

- Data-driven tools and innovation processes for business modelling

The JRC DDBMI develops and improves data-driven approaches (e.g., frameworks, process models, methods, and tools) for business model innovation and provides these approaches for the partner companies. These newly developed approaches will be implemented or applied in several pilot projects by the partner companies. The JRC DDBMI evaluates the pilot projects, particularly the applied newly developed data-driven approaches, to further improve the approaches. The newly developed methods and tools for business model innovation will utilise data analytic methods such as data mining, process mining, and machine learning. The data-driven approaches exploit structured and unstructured data from different sources, e.g., enterprise resource planning, customer relationship management, platforms, marketplaces, the Internet of Things, and social media. The intended outcomes of the JRC DDBMI are generic frameworks for business model innovation for incumbent manufacturers, and new data-driven methods, tools, and process models for business model innovation. The outcomes will be prepared for publication in peer-reviewed journals and conferences. Furthermore, a book on data-driven business model innovation is planned.

Research Subject

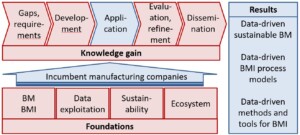

Existing research on business models and business model innovation, data exploration, sustainability, and ecosystems form the basis for the JRC DDBMI’s work. The centre’s scholars use and build on these theoretical foundations. The foundations are applied to incumbent manufacturers and lead to a knowledge gain in the visualised five steps. Challenges come from the company partners and are identified by the centre’s staff.

First, an analysis of the state of the art consisting of literature reviews and empirical studies (e.g., case studies, focus groups, expert interviews) is conducted in cooperation with the partner companies and further relevant companies in order to identify research gaps as well as industrial requirements and needs. Second, new data-driven approaches (e.g., frameworks, guidelines, process models, methods, tools) for business model innovation are developed by utilising data exploitation and data analytics (e.g., data mining, process mining, machine learning, simulation) to fill the research gaps and meet industrial needs. Third, the partner companies implement or apply (newly developed) approaches in several pilot projects. The JRC DDBMI evaluates the pilot projects, particularly the newly developed data-driven approaches, to improve these (new) approaches (frameworks, guidelines, process models, methods, and tools for data-driven business model innovation). Finally, the research results will be published in peer-reviewed journals, peer-reviewed conferences, and a guideline for data-driven business model innovation for incumbent manufacturers will be published in a book.

The results of this rigorous scientific process are:

- Data-driven sustainable business models

- Data-driven business model innovation process models

- Data-driven methods and tools for business model innovation

Work Plan

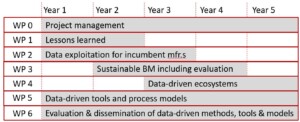

For each work package (1-6), one or more overarching research question(s) is/are formulated that will be answered as the work package’s output:

- WP1 – How can incumbent (manufacturing) companies benefit from the lessons learned from success and failure in (data-driven) business model innovation?

- WP2 – How can data be transformed into value?

- WP3 – How can a business model concept be structured in order to support a sound sustainable (economic, environmental, and social) development of the company utilising the concept? How can outcomes of sustainable (which are defined but not yet implemented) business models be predicted?

- WP4 – How can an (existing) data-driven ecosystem from a manufacturing partner’s perspective be (re)shaped?

- WP5 – How can (available) data-driven tools for business model innovation be developed and utilised? How can (available) data-driven business model innovation processes be developed and benefited from?

- WP6 – How can incumbent (manufacturing) companies benefit from the lessons learned from success and failure in (data-driven) business model innovation? How can data be transformed into value? How can a business model concept be structured in order to support a sound sustainable (economic, environmental, and social) development of the company utilising the concept? How can outcomes of sustainable (which are defined but not yet implemented) business models be predicted? How can an (existing) data-driven ecosystem from a manufacturing partner’s perspective be (re)shaped? How can (available) data-driven tools for business model innovation be developed and utilised? How can (available) data-driven business model innovation processes be developed and benefited from?

Transition Process

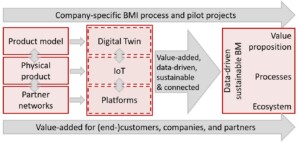

All partner companies involved have data-based model representations of their products in classical systems, such as CAD-based 3D models or ERP-supported bills of materials (BOM), well-established physical products, and successful cooperations with their suppliers, partners, and (end-)customers. Furthermore, all partners have established some new digitalisation or data-driven approaches or at least started such projects.

The second pillar lists aspects to be developed in a follow-up step from the already existing aspects (i.e., product model, physical product, and supplier-partner-(end-)customer network). Digital twins are new solution elements to enable ongoing digital monitoring and active functional improvement of interconnected products, devices, and machines. In addition, the benefits of horizontal and vertical integration in manufacturing are targeted by the introduction of digital twins. The transformation from physical products to smart connected products and their utilisation for servitisation, value creation, value delivery, and value capture is key for manufacturing companies. Platforms are becoming increasingly important for the activities of companies, and even if companies are not (yet) developing platforms, they should consider the opportunities they offer. Digital twins, smart connected things, and platforms can be seen as enablers of data-driven value propositions, optimised or autonomous processes, and dynamic collaboration with partners in an ecosystem for data-driven business models of incumbent manufacturers. This results in value creation for (end-)customers, partners, and the respective companies.

Business Model Innovation Process Model

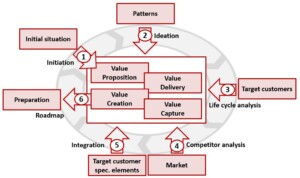

This conceptual process model for iterative business model innovation is based on the state of research and findings on the topics of business models and business model innovation, as well as creating competitive advantages, agility, and change projects. The conceptual process model describes an incremental, iterative, recursive, and reflective procedure that comprises six phases: (1) initiation, (2) ideation, (3) life cycle analysis, (4) competitor analysis, (5) integration, and (6) roadmap. These phases describe business model innovation from initiation to the final roadmap for its subsequent implementation (which is not part of the process model). Depending on the progress and insights gained, the phases are carried out iteratively and are repeated as necessary. At the centre of the process model is the business model with its four dimensions and nine elements. In each phase, one to all of the nine elements of the business model are questioned, adapted, further developed and, if necessary, discarded. Phase by phase, the maturity of the business model is increased in terms of becoming more target customer-oriented, strategy-compliant, and value-creating.

Link to the CDG Homepage:

Contact

Manuel Brunner MSc

PhD Candidate

Josef Ressel Centre for Data-Driven Business Model Innovation (JRC DDBMI)

University of Applied Sciences Upper Austria

Wehrgrabengasse 1-3

4400 Steyr/Austria

Phone: +43 5 0804 33293

Mobil: +43 664 80484 33293

E-Mail: manuel.brunner@fh-steyr.at

Web: www.fh-ooe.at

Web: https://coe-sp.fh-ooe.at/